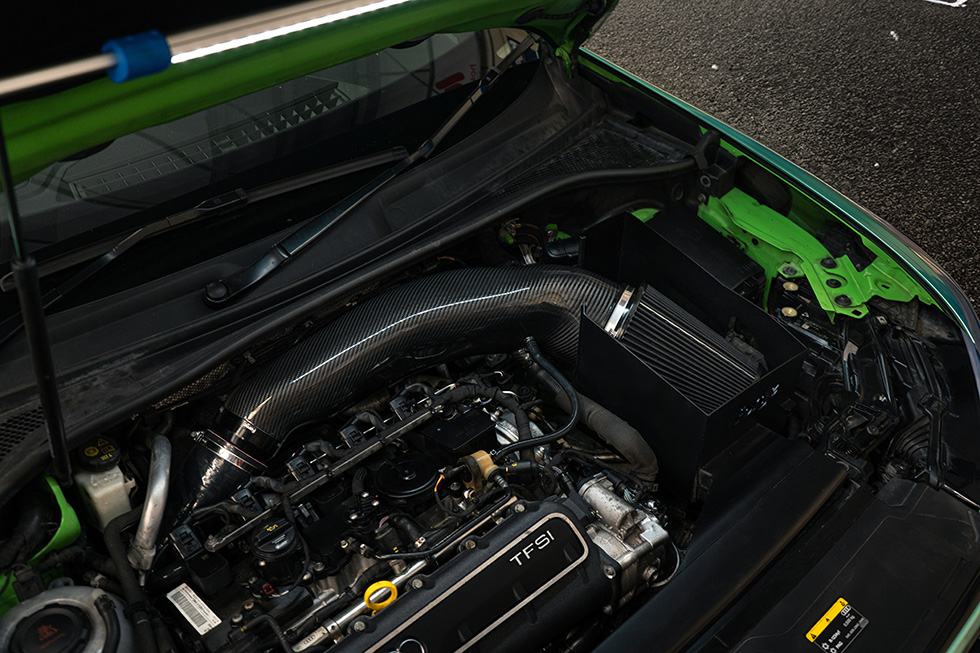

Forge Motorsport Intercooler For Audi RS3 (8Y)

FORGE MOTORSPORTHighlights:

- Peak gains of 17bhp

- Gains of 14lb/ft of torque

- 153% volume increase

- Hand fabricated in the UK

- Kit includes all necessary fittings and instructions included

- Lifetime warranty

Following on from our very successful intercooler and performance products for the RS3 8V chassis, the Forge intercooler for the RS3 8Y chassis builds on our reputation for delivering cooling solutions, that offer real-world increases in power and impressive temperature drops. Whilst the 8Y chassis shares many components with the older 8V, the space available behind the bumper is a different shape, and the crash bar has also changed. This required a whole new intercooler and crash bar setup for this latest chassis.

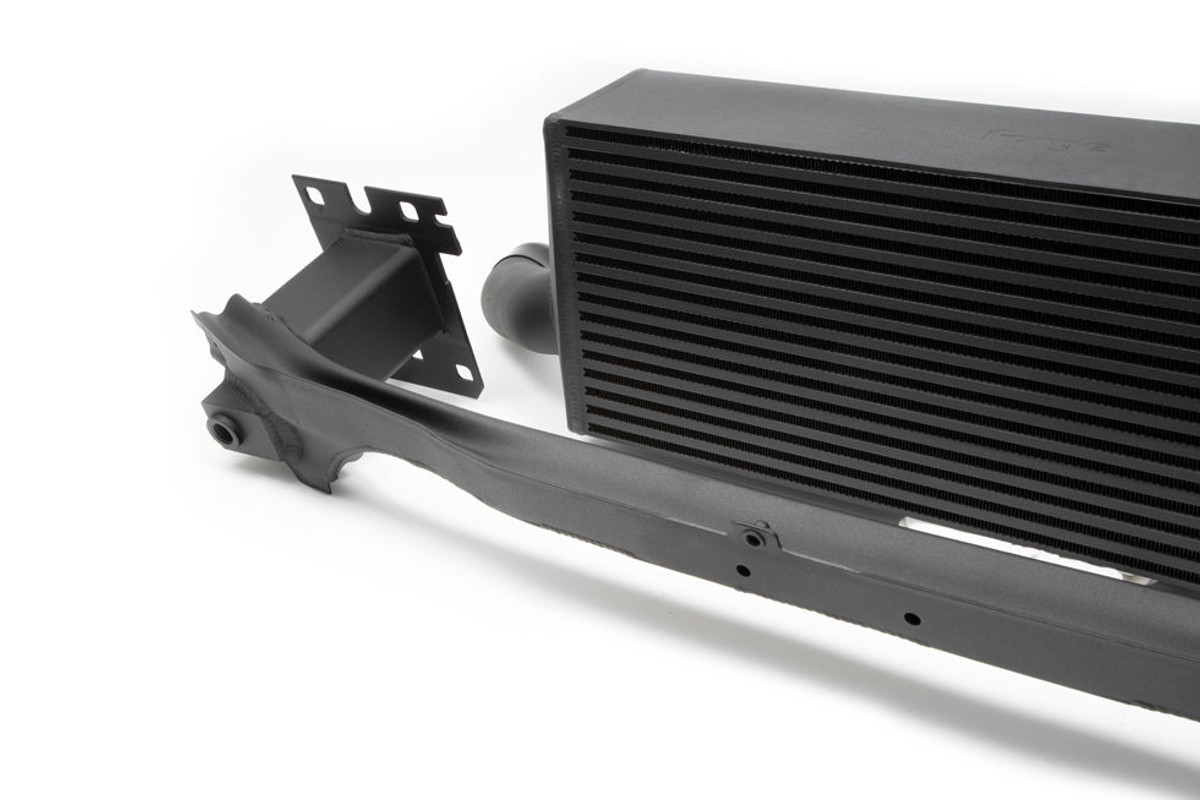

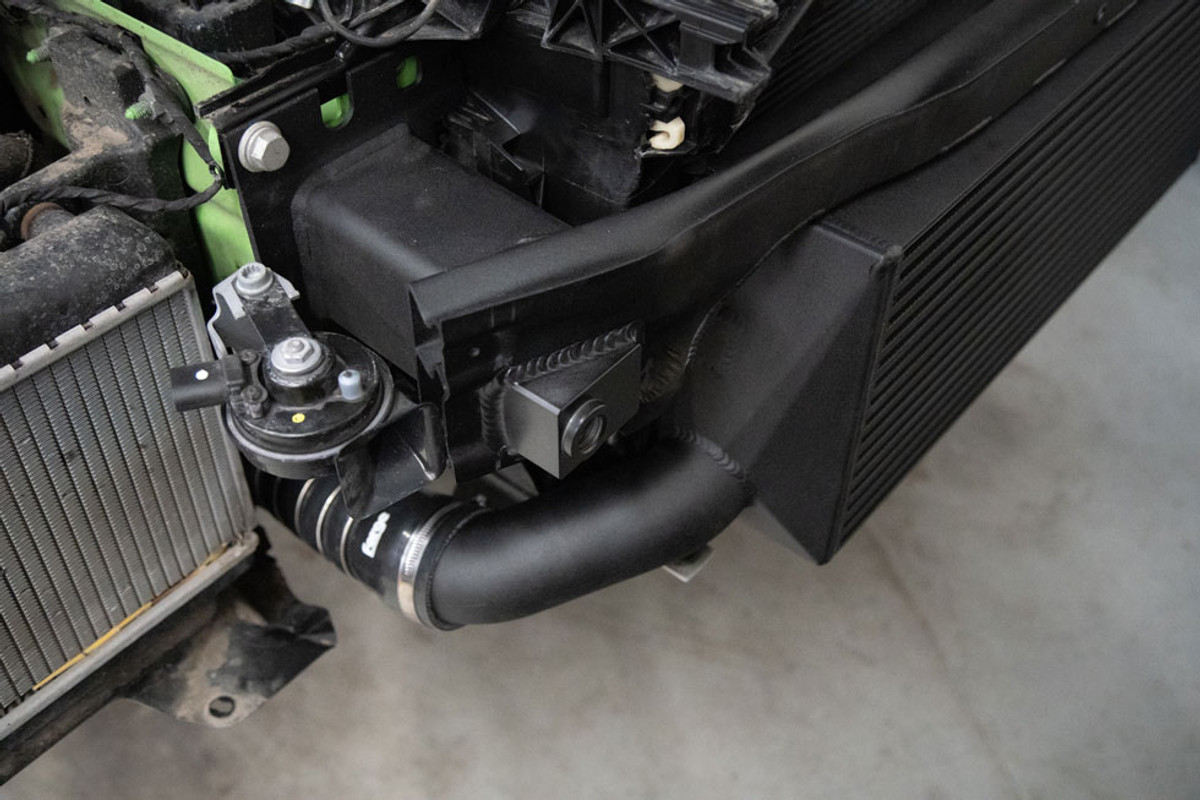

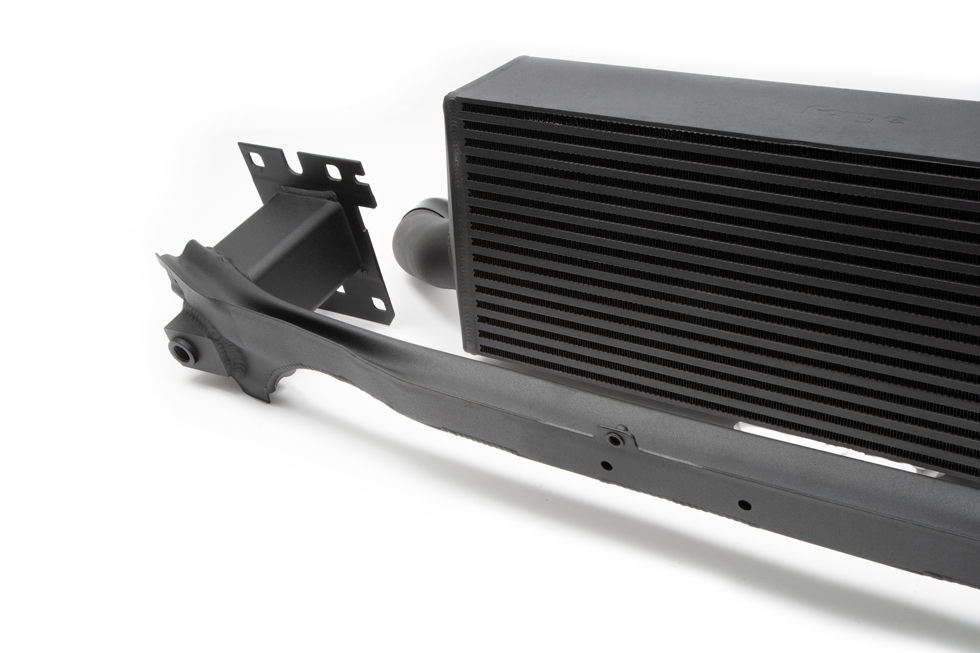

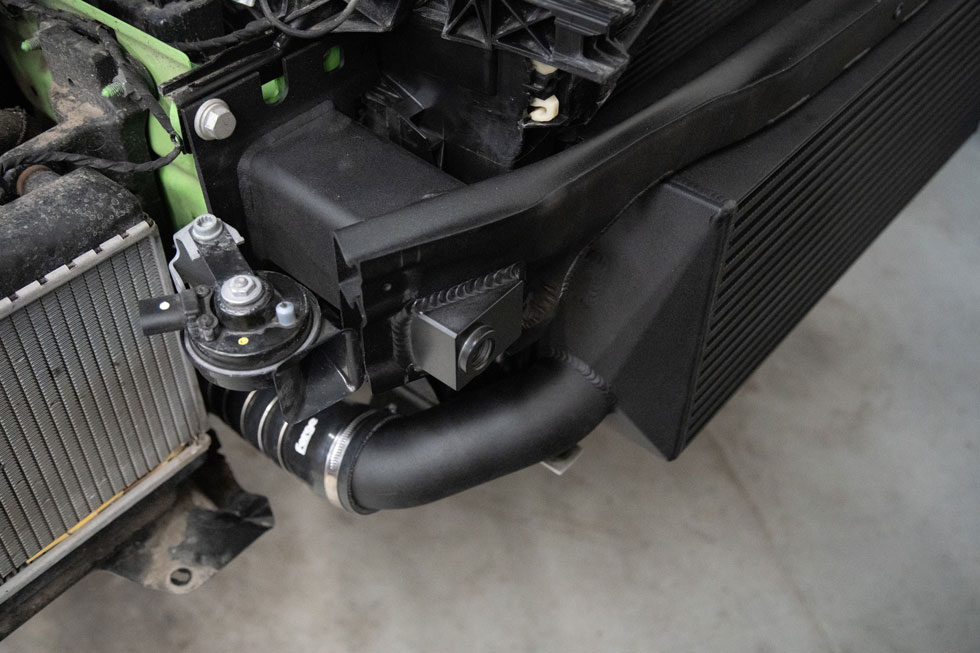

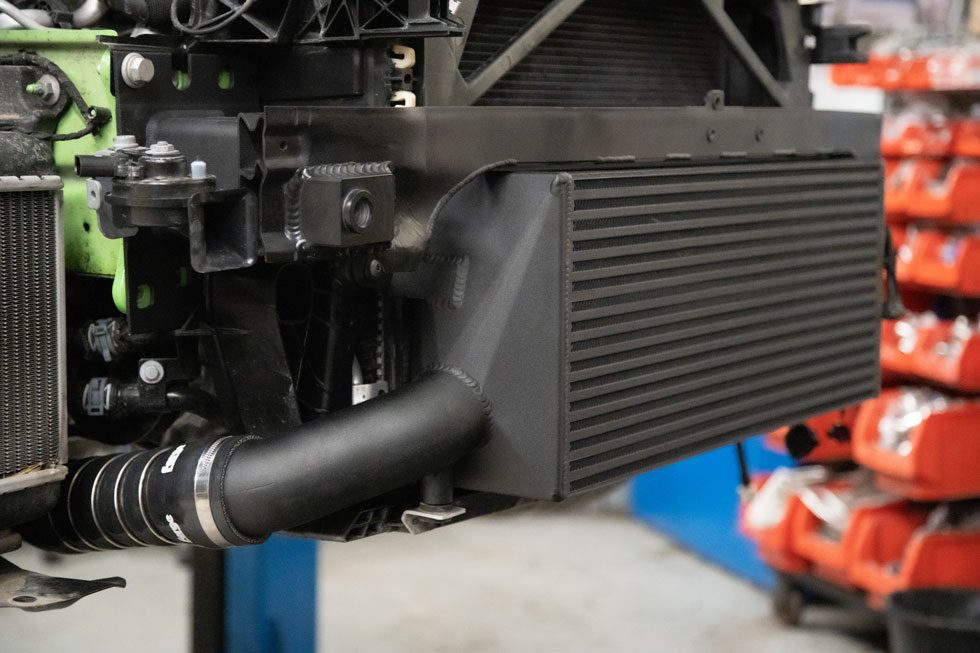

The crash bar Audi has fitted to the RS3 8Y is made of steel, our Forge Motorsport intercooler kit utilizes a genuine Audi alloy crash bar, that we have cleverly modified in-house, in order to accept the enormous race intercooler. This in-turn when compared to the weight of the standard OEM intercooler and crash bar, is only 1kg heavier, meaning the additional weight has no detriment to performance and is far outweighed by the power gains achieved when it is installed. After our skilled fabricators have carefully crafted this piece of automotive artwork, we then finish both the crash bar and intercooler in our standard black finish powder coat for maximum longevity and that OEM+ look.

The RS3 8Y core is a huge 640x250x130 with a bar and plate design. This gives it an impressive 55% increase in surface area over the stock OEM item, and an even more awe-inspiring 153% more volume. The end tanks are made with integrated pipes to retain the stock boost hoses, though you can also replace the standard hoses with our FMKT033 boost hose set if you so wish. This can help prevent hose expansion and failure when running increased boost pressures, just like on the 8V chassis.

Before getting to work on the Dyno, we spec’d three different types of cores, one of these being bar and plate, and two being a tube and fin construction, with all three cores having different internal and external fin pitches and configurations. This is to ensure we deliver the best possible products for our customers, which is proven time and time again by one of the world leaders in the performance industry.

Why do we test different cores?

Here at Forge Motorsport, when developing an intercooler, we will test several different cores for each application. For example, a bar and plate style core, a tube and fin style core along with different fin pitches and heights, e.g., 22 ,17 or 12 fins per inch, as well as changing the internal fin pitches/shapes and density within the tube enabling to fine tune the amount of pressure drop the intercooler produces.

Pressure drop is not always a bad thing, as our testing and research has proven on various projects, this is because the pressurized air velocity is being stalled by the pressure drop within the cooler, thus allowing more time to cool the air within the cooler itself as air passes through the non-pressurized face of the core, that is open to the atmosphere. Too much pressure drop can of course have a problem on the higher performance engines as the intercooler reaches its maximum efficiency, the turbo must work a lot harder to force the air through the core. This in-turn creates higher inlet air temps (IAT’s), as the turbo is creating more heat as it is working harder. No pressure drop can also prove to be inefficient as the cooler will not lower the charge temperature again, resulting in higher inlet air temperatures.

Dyno Testing

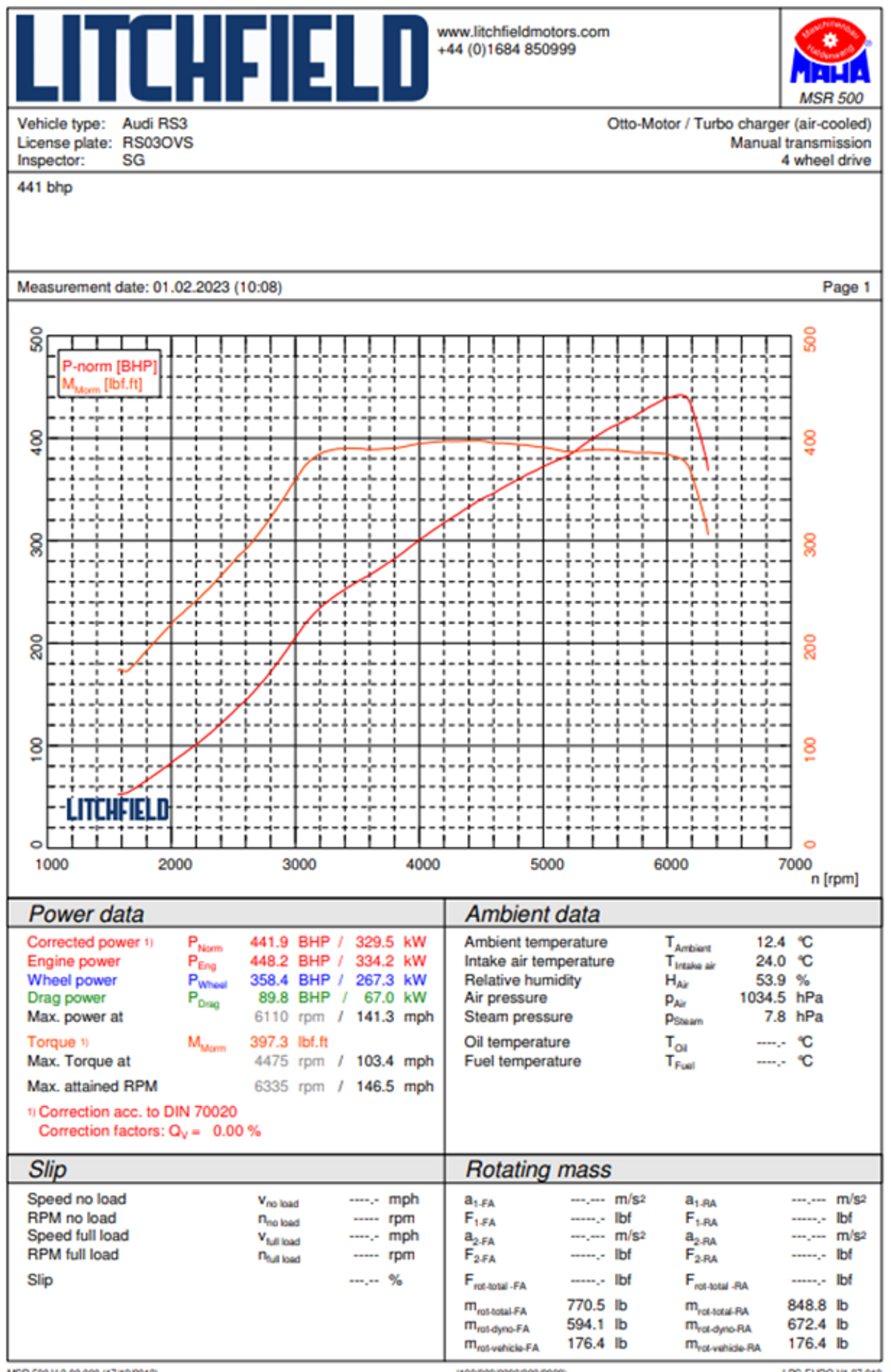

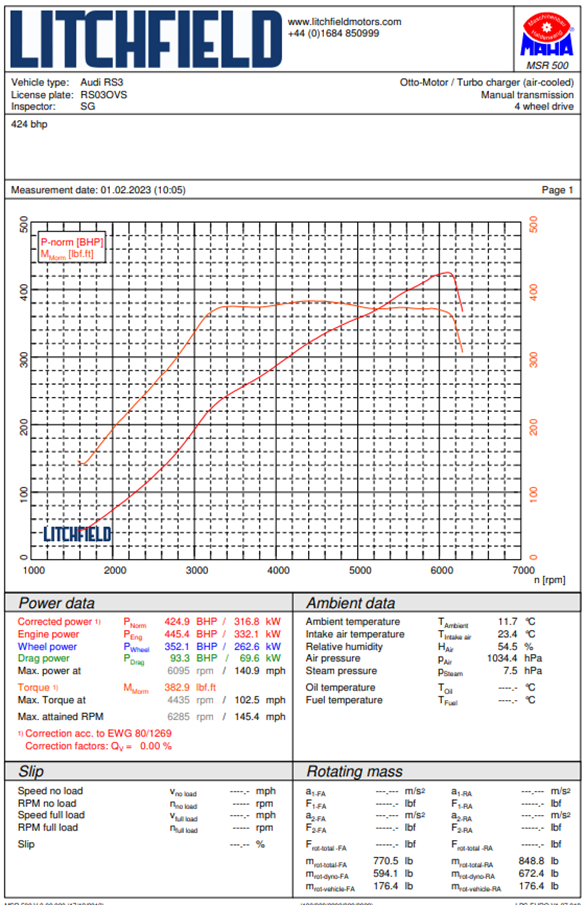

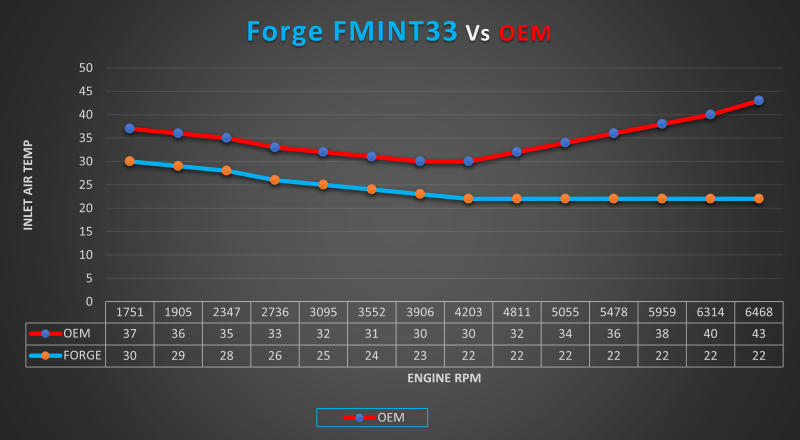

Testing was completed independently on Litchfield’s Maha dyno, manufactured by the same people who currently supply BMW M Sport and Mercedes Benz for all their engine calibration and dyno testing. The graph below shows the rolling road test for the OEM intercooler, for both tests we let the car heat soak on the dyno until the radiator fans tripped on and off (which gives an inlet temperature of 36°C), then do a dyno pull from there. This gives a more consistent result and reflects real-world driving conditions more accurately.

On the vehicle we used for testing and development, it made 424.9BHP and 382.9lb/ft. This vehicle was completely standard apart from being fitted with a Milltek cat back performance exhaust system. The measured power output is marginally more than the figures Audi quote, with a data logged peak intake temperatures of 43°C at 6550RPM.

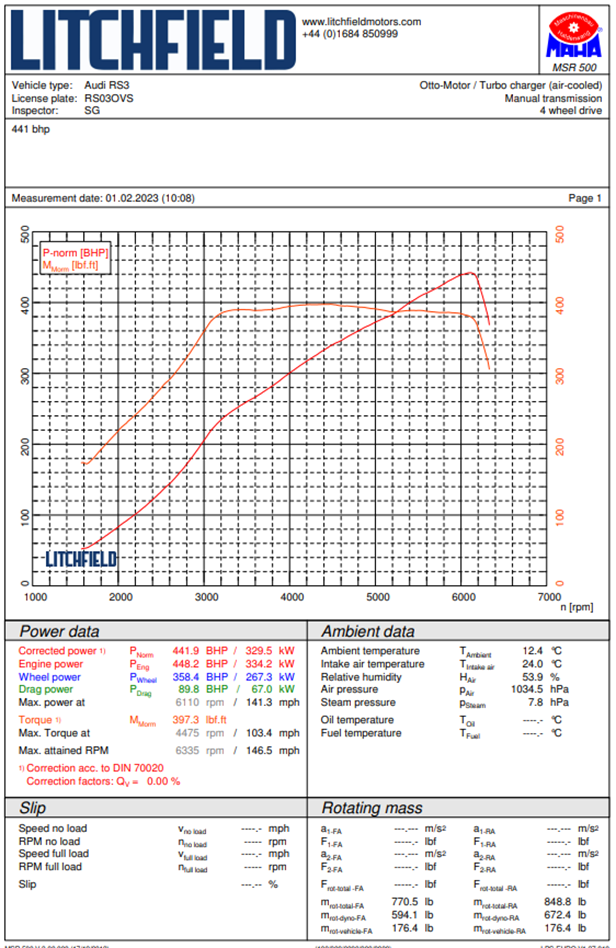

We then swapped out the OEM intercooler with the FMINT33 race intercooler to continue testing. The same car made 441.9BHP and 397.3lb/ft of torque with a peak recorded inlet temperature of 21.8°C at 6450RPM, this equates to a gain of 17BHP and 14lb/ft, and a drop of 22°C. Gains on mapped cars will likely be even more impressive as the stock intercooler core struggles on just stage 1 mapped cars, as previously found on the older RS3 that still uses the DAZA engine. From the independent testing and results pictured, you can see the intercooler really does deliver you unparalleled levels of performance. The Forge intercooler cools faster and delivers a far greater drop in temperature compared to OEM intercooler.

The intercooler has all the necessary hardware and comprehensive fitting instructions to install the kit in approximately 4 hours depending on competency and tools available.